Here are a few impressions from our first digital live event for all those who were unable to experience ZIA Stars live.

The winners of the Zambelli Innovation Award 2020 have been announced!

The best projects from the categories of product innovation, process innovation and new ideas were rewarded and honoured by the jury members on 10 March.

We would like to extend our warm congratulations once again at this point!

The ZIA team thanks all contributors and participants for their commitment and energy. They all make a difference in the company’s ongoing development, as exemplified by Franz Zambelli Sopalù and Franz Grill whose idea of innovation has always pointed the way forward for Zambelli.

Many thanks!

Here are a few impressions from our first digital live event for all those who were unable to experience ZIA Stars live.

Category

Product Innovations

Implementation

Implemented

Originator

Development Team Budweis/CZ with Hauer Josef and Haško Viliam

Team members

Hauer Josef, Haško Viliam

Site

Budweis/CZ

Description

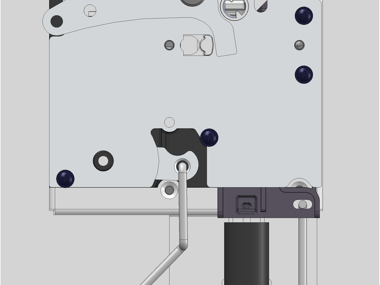

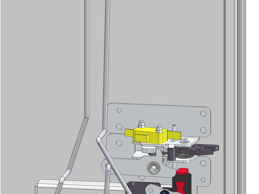

The SML Atlas lock or central locking unit acts as the central point for operating a caravan or motor home door. The Atlas lock enables both 2-point and 1-point locking. A free-wheel function for the outside lock and a central locking system can be adapted.

The SML lock is available in 1-point and 2-point locking variants and consists of several components that are connected by rods. They are arranged in almost any position on the SML door. The central locking is coupled to the central closing unit. This has the advantage that the motor for the central locking can be retrofitted at any time.

Jury’ opinion

This project is the clear winner in the Product Innovation Category thanks to the excellent ratings, the functional improvement of the lock and the associated high benefit for a TOP customer with the prospect of expanding the customer base.

Category

Product Innovations

Implementation

implemented

Originator

Patrick Bell

Team members

Klaus Blöchl, Patrick Moser

Site

Wegscheid

Description

Zambelli Pazio is a bookcase and usable surface in one.

The book stocks are placed around the freely designable usable surface. Divided in the middle, two side walls can be opened by electric motor – creating a two-sided entrance. The shelves move silently and are controlled by manual switch, mobile app or PC. Customers can always design the inner life of the Zambelli Pazio any way they like.

A proven option is to create sound-insulated reading islands. A cooperation with COR Sitzmöbel was launched to design the inner life.

By installing Zambelli Pazio, you create space for visitors to linger undisturbed without any loss of capacity.

Jury’s opinion

This project is the winner in the Product Innovation Category owing to its trend-setting expansion of our product range, the versatile use of this shelving system and its highly attractive look.

Category

Product Innovation

Implementation

in testing

Originator

Metalworking apprentices with Martin Matschiner & Severin Geier

Site

Haus im Wald

Description

The gutter hook set for sandwich panels can be easily pre-assembled in the workshop or “on site” with the installation device for sandwich gutter hooks. In the process, the gutter hook is clamped to the top bracket holder to fit the shape by means of a quick-clamping system and then screwed together. This eliminates the need for potentially time-consuming installation and dangerous situations on the scaffolding or lifting platform.

Initial designs for a series part have since been prepared. The product is intended to boost sales of the sandwich gutter hook system. Zambelli is therefore offering solutions by experienced experts for experienced experts.

Jury’s opinion

The excellent ratings, the one-time market opportunity due to the unique selling proposition and the well-conceived safety benefit during installation make this project the winner in the Product Innovation Category. The outstanding commitment shown by our apprentices deserves a particular mention as well!

Category

Process Innovation

Implementation

in testing

Originator

Josef Bschlangaul

Team members

Wolfgang Völkl, Günter Weber

Site

Stephansposching

Description

A narrow verge up to a length of 6.40 m can now be edged as an alternative to the standard design with verge suspension profile and cover plate. The folded narrow verge sheets must be joined, e.g. by welding, for longer versions.

The narrow verge is produced in the current waist roll former as a fitted sheet from a roll-formed RIB-ROOF profile sheet according to the length of the RIB-ROOF profile sheets and the required construction width. This enables simple and economical installation owing to fewer components. This product solution is especially appealing to architects and perfectly reflects our principle of “I just do it”! Zambelli will benefit from this through additional sales potential and a unique selling proposition.

Jury’s opinion

The design upgrade for our proven tested RIB-ROOF system is more than just a visual

improvement, as it focuses heavily on the needs of the machine and uses current machinery. Altogether a winning project in the Process Innovation category.

Category

Process Innovation

Implementation

implemented

Originator

Csaba Nemeth

Site

Györköny/HU

Description

As accessory items for downpipes, the outlet and gooseneck products were manufactured by hand in a laborious process until a year ago. Only very experienced and competent workers were able to complete this very elaborate task.

This manufacturing process has now been optimised. The tube is manufactured on a proprietary machine built in-house in a first step. Then the typical gooseneck is “twisted” onto the tube using a device that was also developed and manufactured in-house.

This process innovation saves time as well as money

Two systems have already been built for the 100 mm and 76 mm sizes, and others will follow shortly.

Jury’s opinion

This project is an innovation that can be built on throughout the portfolio. This project is a clear winner in the Process Innovation Category thanks to the measurable quality improvement and the unique selling proposition. The project is made even better by the in-house manufacturing and machine design process that make it the winner in the Process Innovation category.

Category

Process Innovation

Implementation

implemented

Originator

Ludwig Beismann

Site

Wegscheid

Description

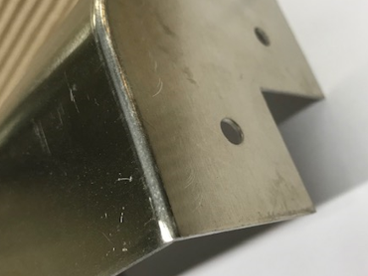

The aluminium corner covers consist of 3 parts in total that are joined using the laser welding machine. The look of these parts is extremely important, so they have to be ground and then polished after welding. The fresh idea is designed to smooth the weld seam.

A simple machine with two pressure rollers was developed. One pressure roller acts as the drive roller, which moves the corner cover and in doing so “presses” the entire length of the edge or weld seam against the second pressure roller. This generates sufficient counterpressure to “crush” or smooth the unevenness in the weld seam.

The benefit of this method on the corner covers is that it eliminates the production of sanding dust, significantly reducing the burden on employees at the workplace and on the environment.

Jury's opinion

This project is a deserving winner of the Process Innovation Category thanks to its customer benefits, the product improvements through in-house design and the extremely positive environmental impact.

Category

New Ideas

Implementation

implemented

Originator

Zambelli metal/Romania with Santa Reka

Site

Sfantu Gheorghe/RO

Description

Zambelli metal decided to offer a dual apprenticeship based on the German education system and in cooperation with the Sf Gheorghe technical college.

After several discussions with various offices and ministries, 15 apprentices were able to start dual training at Zambelli in 2019. This form of training remains unique in the entire Covasna district.

It aims to counteract the shortage of skilled workers and to train the next generation of employees for Zambelli metal without relying on others. In doing so, the company is seeking not only to give young people from the region the opportunity to enjoy excellent training in a down-to-earth, family-run company, but also to make Zambelli metal fit for the future with a young generation of well-trained specialists.

Jury’s opinion

This project lays the foundation for reshaping the future across the board and is highly attractive for apprentices. It is a clear winner in the New Ideas Category owing to its contribution to the quality of young employees and to strengthening their strong bond with our company.

Category

New Ideas

Implementation

no implementation as yet

Originator

Jürgen Dankesreiter

Site

Haus im Wald

Description

In Zambelli’s production, the main warehouse is currently managed with fixed bays and undefined block storage. A more flexible and computer-supported storage space allocation via hand scanner would be beneficial to improve efficiency in the use of vacant storage bays.

A system of this kind would enable short-term creation of storage space for non-stocked items and surplus articles. Above all, shelf storage spaces would be used more efficiently and space would be freed up in open areas, adding to overall warehouse capacity.

Jury’s opinion

The functional evolution towards modern warehouse logistics, the advantages in the utilisation of space resources and the high probability of implementation at all Zambelli locations make this project the winner in the New Ideas Category.

Category

Product Innovation

Implementation

in testing

Originator

Heinrich Denk

Site

Haus im Wald

Description

The universal ceiling bracket is a real all-rounder: as a bracket for lighting, supply lines as well as for media installation.

Installation on the underside of the ceiling follows the same procedure for all variants and is easy to perform. The ceiling bracket is positioned in the bead of the trapezoidal profile and screwed in place. The required supply lines and components are installed there in a protected space.

This idea first came during construction of the new extended dispatch facility in Haus im Wald. Heinrich Denk was looking for a compact and cost-efficient solution for mounting the lighting on the ceiling with impact-protection.

What he eventually created was a new product: A universal ceiling bracket that can be used for versatile purposes. A number of experts have already praised the advantages of the bracket system during inspections of the facility.

Jury’s opinion

The employee’s idea is a successful and inventive solution to a problem, a versatile and attractive product that saves space and offers market potential as well.

The originator has been with the company since 21 September 1981 and consistently shown dedication. This honorary award also recognises his many years of imaginative work.

Zambelli Holding GmbH Passauer Straße 3+5, D-94481 Grafenau/Haus im Wald

Phone +49 85 55 409 0 E-Mail info@zambelli.com