Foaming technology adds a profitable component to the business division of industrial metalworking. The Zambelli locations in Wegscheid und Budweis are equipped with the suitable machinery for foaming seals, panels, caravan doors and flaps.

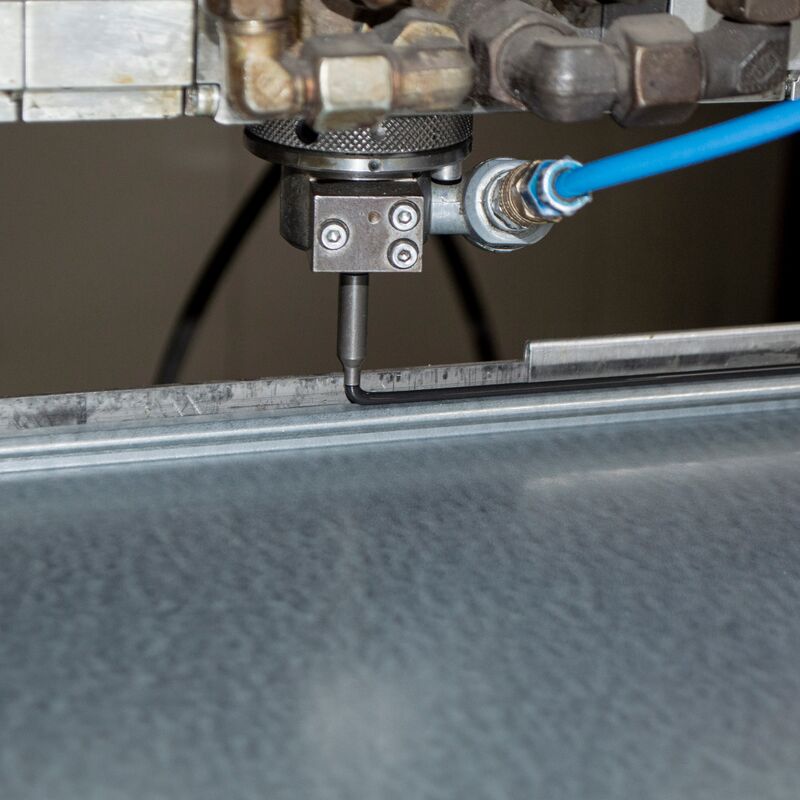

The foaming of seals, for example on control cabinet doors, control cabinet side panels or covers, is a vital area of process technology in industrial metalworking. These seals can be applied to the sheet metal parts in variable cross-sections, without requiring an additional rubber sealing. The foam mass can be adapted ideally to fit the components thanks to the soft core of the sealing bead and the wide variety of possible contours such as circles or tight radii. Foam technology also saves valuable time during production compared to the mounting of rubber sealings.

Another main area of application is the foaming of panels, caravan doors and flaps. This process involves joining two sheet metal or plastic shells, while foaming the intermediate space. This sandwich construction is highly effective thanks to its heat-insulating effect: the thermal separation of the outer shell and inner shell helps to stop condensation forming on the interior of the enclosure. This also reduces installation work on construction sites, as separate insulation is superfluous.

Zambelli Holding GmbH Passauer Straße 3+5, D-94481 Grafenau/Haus im Wald

Phone +49 85 55 409 0 E-Mail info@zambelli.com